Preventative Maintenance Services

Proactive Electrical Maintenance for a Reliable Operation

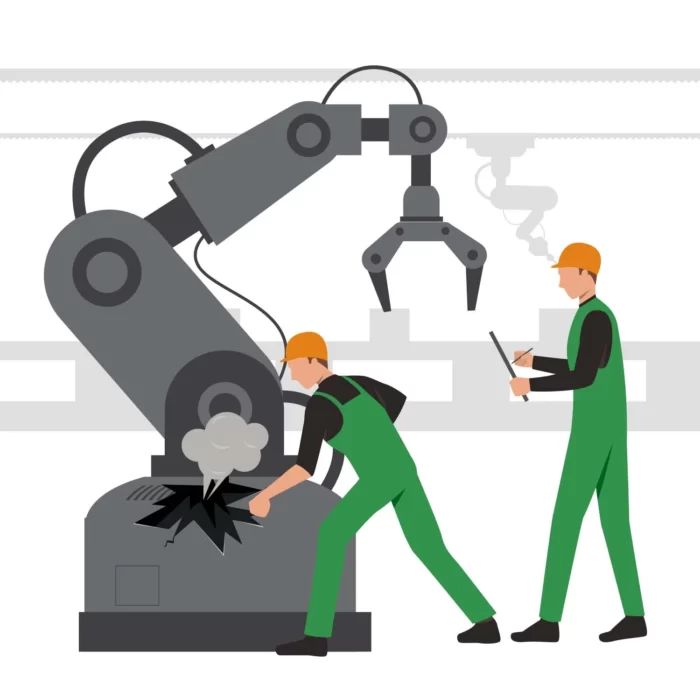

At Power Glow Electrical, we understand the critical role that well-maintained electrical equipment plays in ensuring a safe and efficient work environment. Implementing routine preventative maintenance is key to avoiding unexpected electrical failures, costly repairs, and operational downtime.

Stay Ahead with Preventative Maintenance

Electrical issues often arise without warning, leading to disruptions that impact productivity and safety. A structured maintenance plan allows you to identify, repair, or replace problematic electrical equipment before it fails—keeping your business running smoothly.

The Cost of Neglecting Maintenance

Ignoring proper equipment upkeep can result in expensive repairs, hazardous conditions, and unnecessary downtime. Investing in preventative maintenance (PM) ensures long-term reliability, improved efficiency, and cost savings for your operation.

Key Benefits of a Routine Electrical Maintenance Program

A well-structured preventative maintenance routine provides significant advantages, including:

Minimized Downtime – Avoid unexpected electrical failures and maintain steady workflow.

Cost-Efficiency – Reduce emergency repairs and extend equipment lifespan.

Improved Safety & Compliance – Ensure adherence to industry safety standards.

Optimized Performance – Keep electrical systems operating at peak efficiency.

Enhanced Reliability – Strengthen the dependability of essential electrical equipment.

Trust Power Glow Electrical for Expert Maintenance Services

Our team of professionals is dedicated to providing comprehensive electrical maintenance solutions, helping you prevent costly disruptions and keep your business running efficiently.

Protect your operation today—schedule your preventative maintenance service with Power Flow Electrical!

Services Offered

Fast || Reliable || Experienced || Attention to Detail

Safety

Protect your workers from the risk of sudden equipment breakdown.

Optimal Performance

You will enjoy the best return on the investment made on your equipment by making sure it is continually functioning optimally.

Prolonged Equipment Lifespan

Take Better care of your machinery to ensure your assembly last longer.

Save Time & Money

If you address signs of wear and tear early on you will save valuable time and cost incurred by comprehensive repair jobs, overhauls, and replacements.

How to establish a maintenance routine:

It can take a while to establish a new operational routine in your business. But the benefits of scheduled maintenance for your equipment will be well worth the effort.

Clean your equipment

Buildup of grime, dust and other particles can cause equipment failure. The parts and components of your unit should be evaluated by a professional on a routine schedule to look for worn parts before system failure happens.

Repair Broken Parts

Parts of equipment wear out after years of use. When you notice that you have a broken or noisy part, it is essential to have this repaired by a professional technician. Stay on top off it all!

Implement Maintenance Scheduling

Look at your appliance manuals to look at the frequency of maintenance necessary to maintain optimum performance. The frequency of maintenance is typically specified by the number of hours of use.

The benefits of working with an equipment repair service company like Power Flow Electrical Solution, is that we will be able to undertake this scheduled maintenance for you.